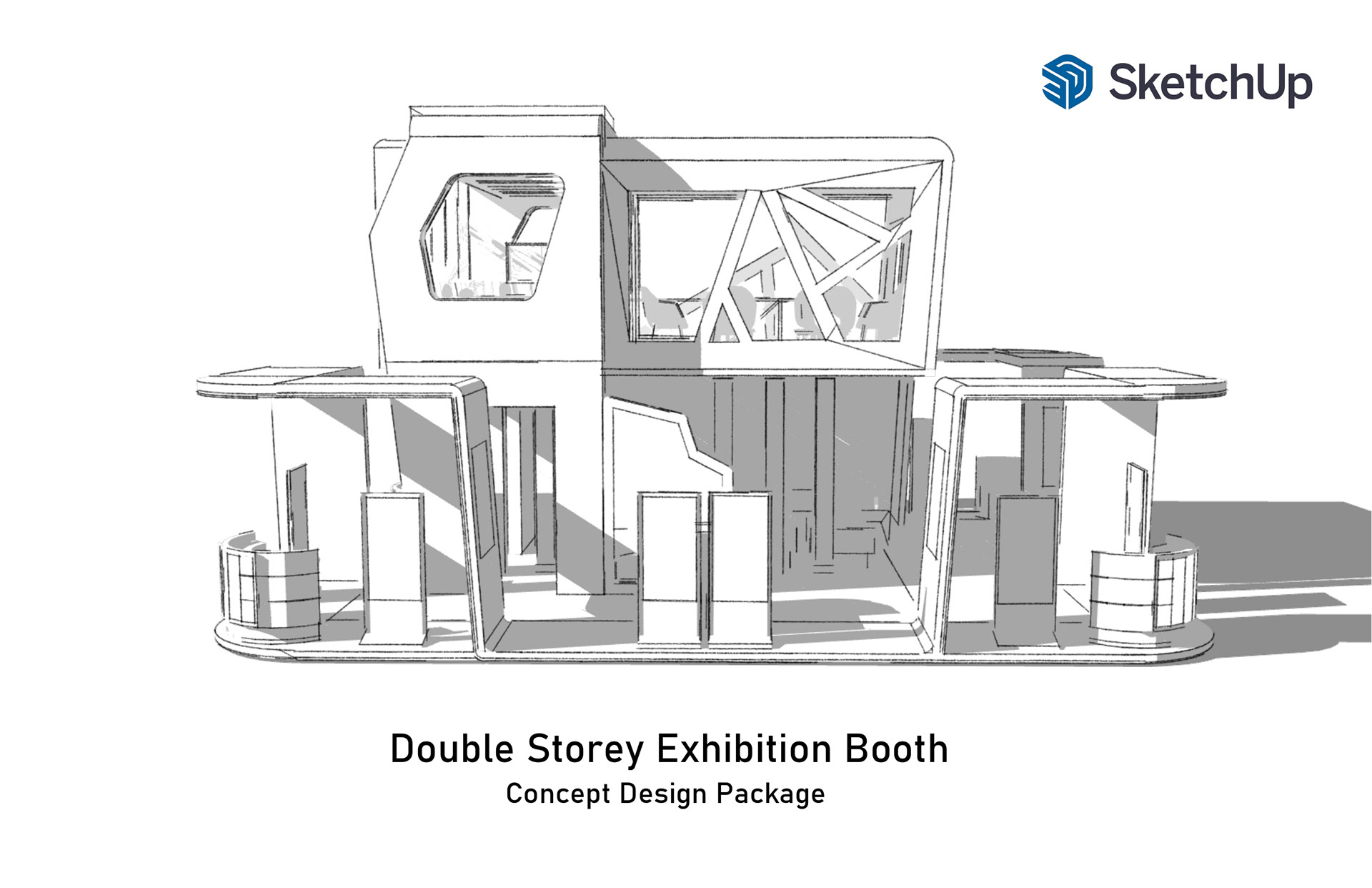

Technical Fabrication (3D-to-2D) Dicut Conversion

Project Overview

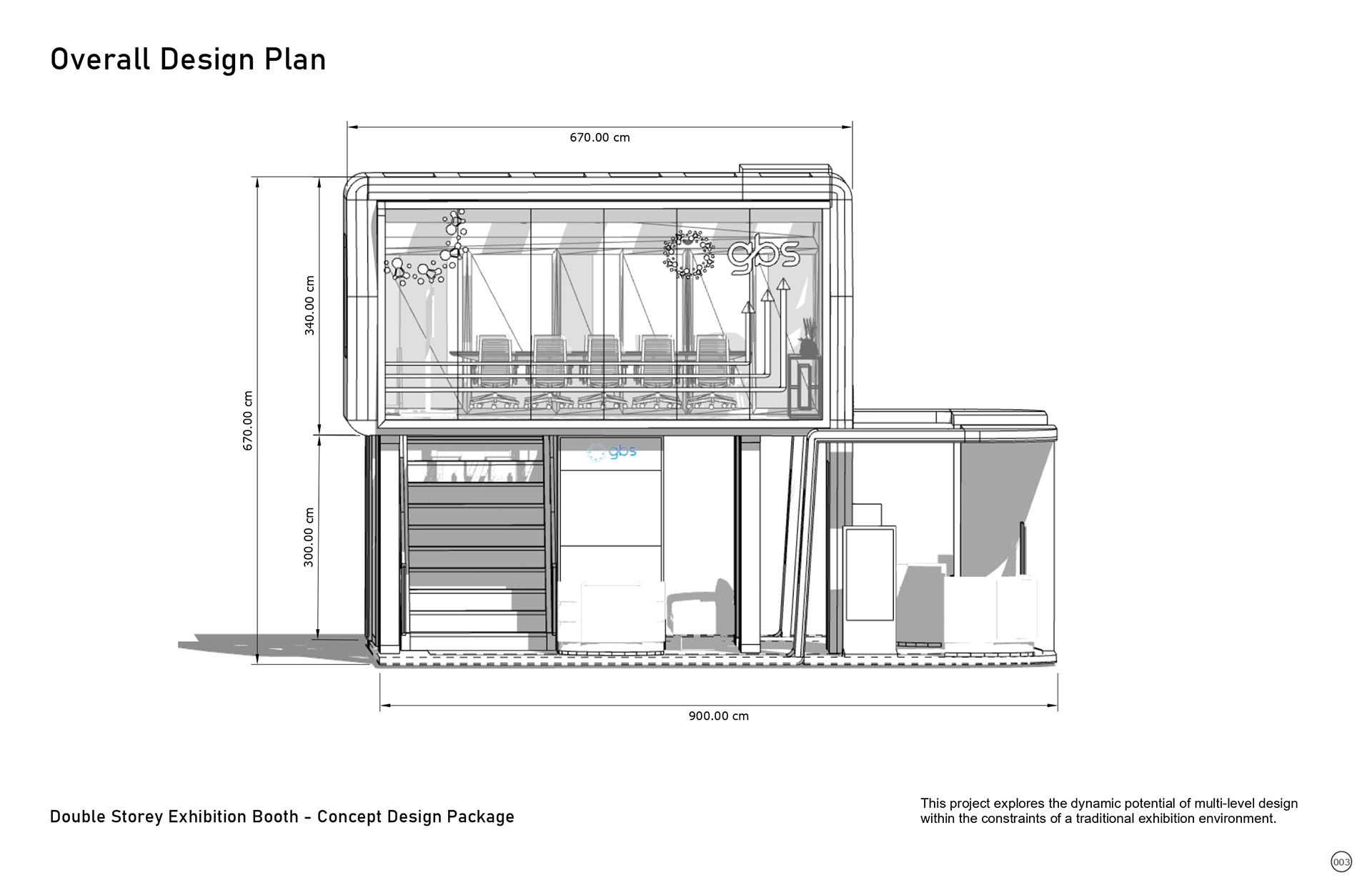

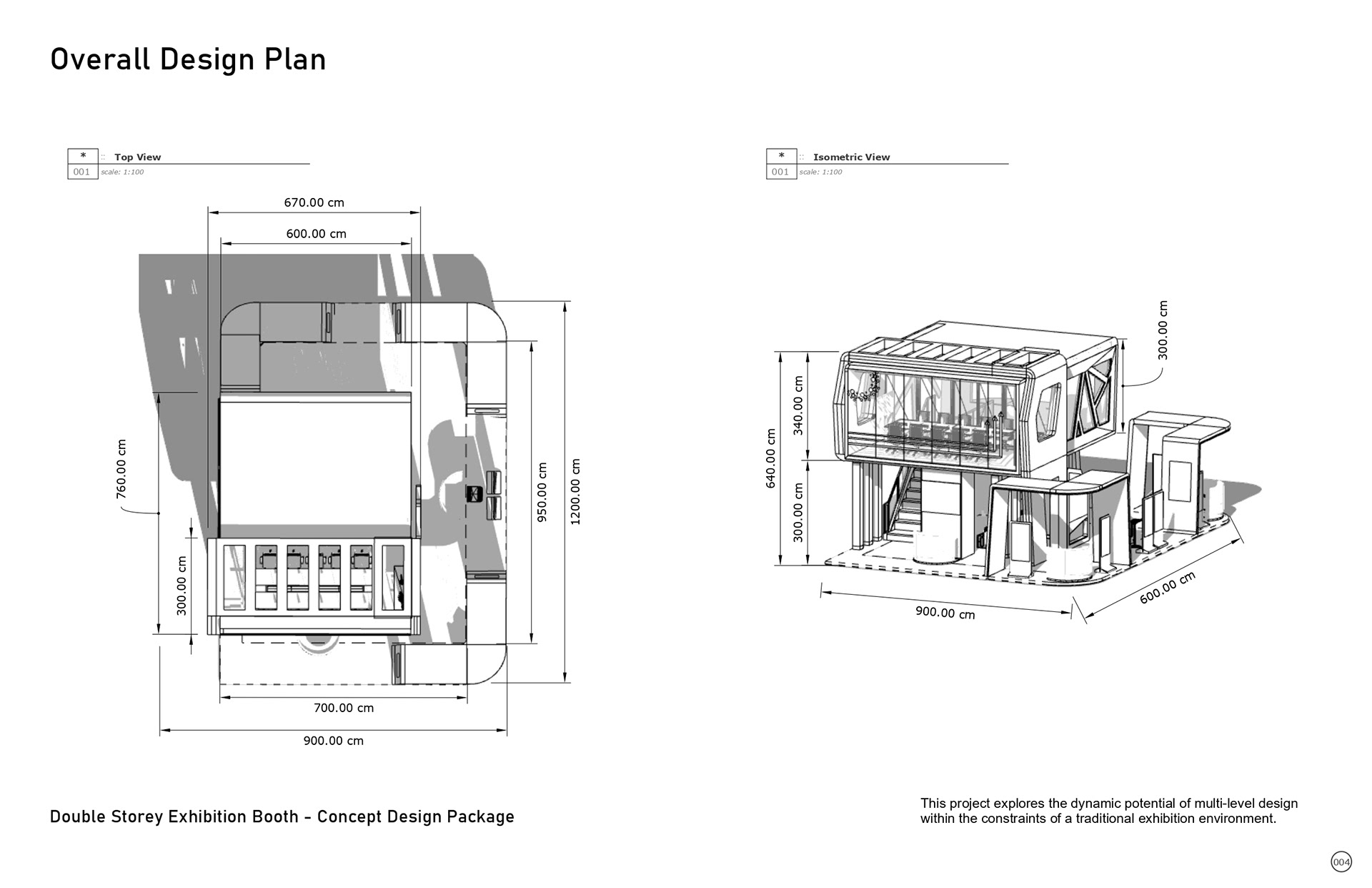

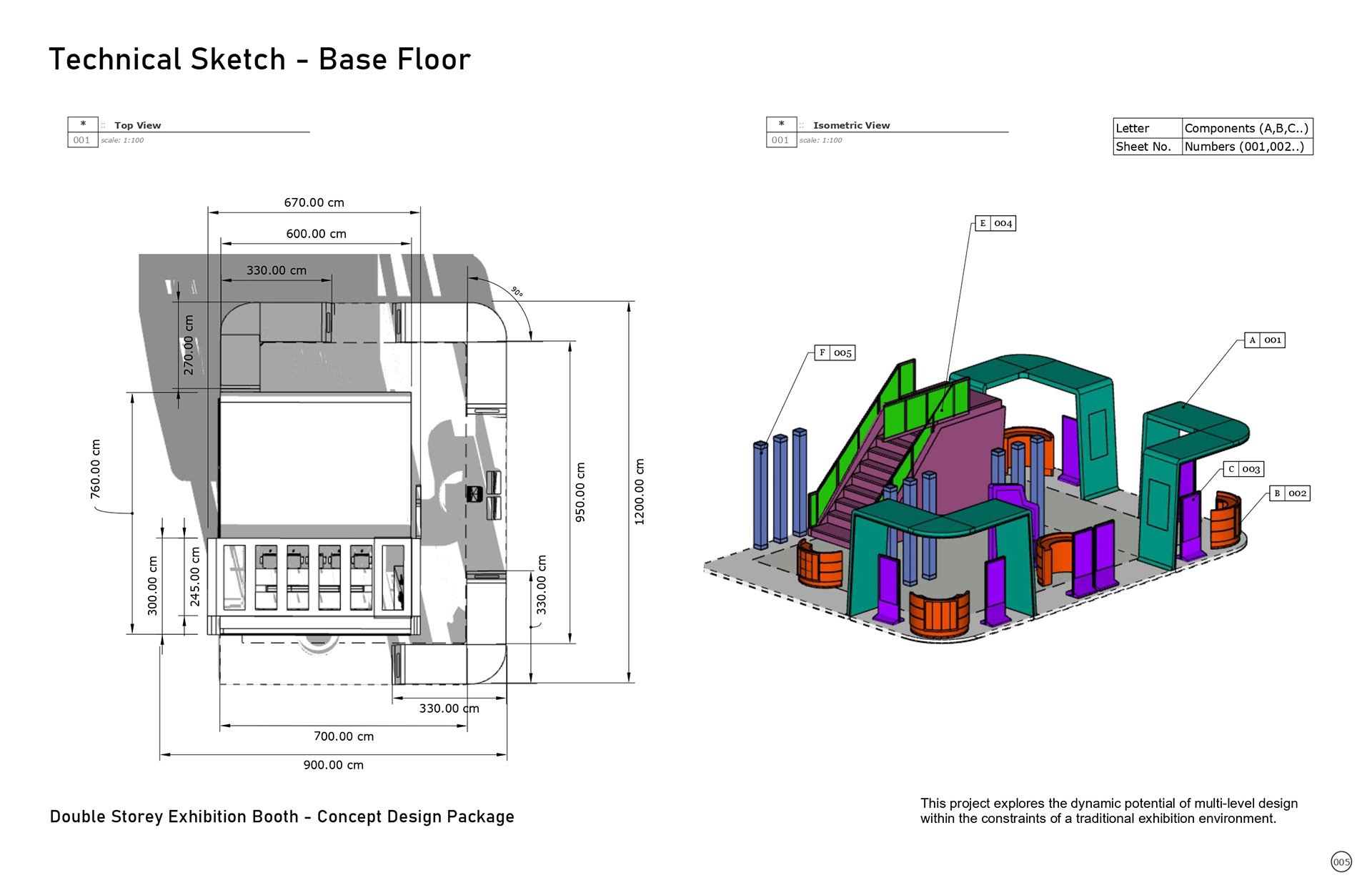

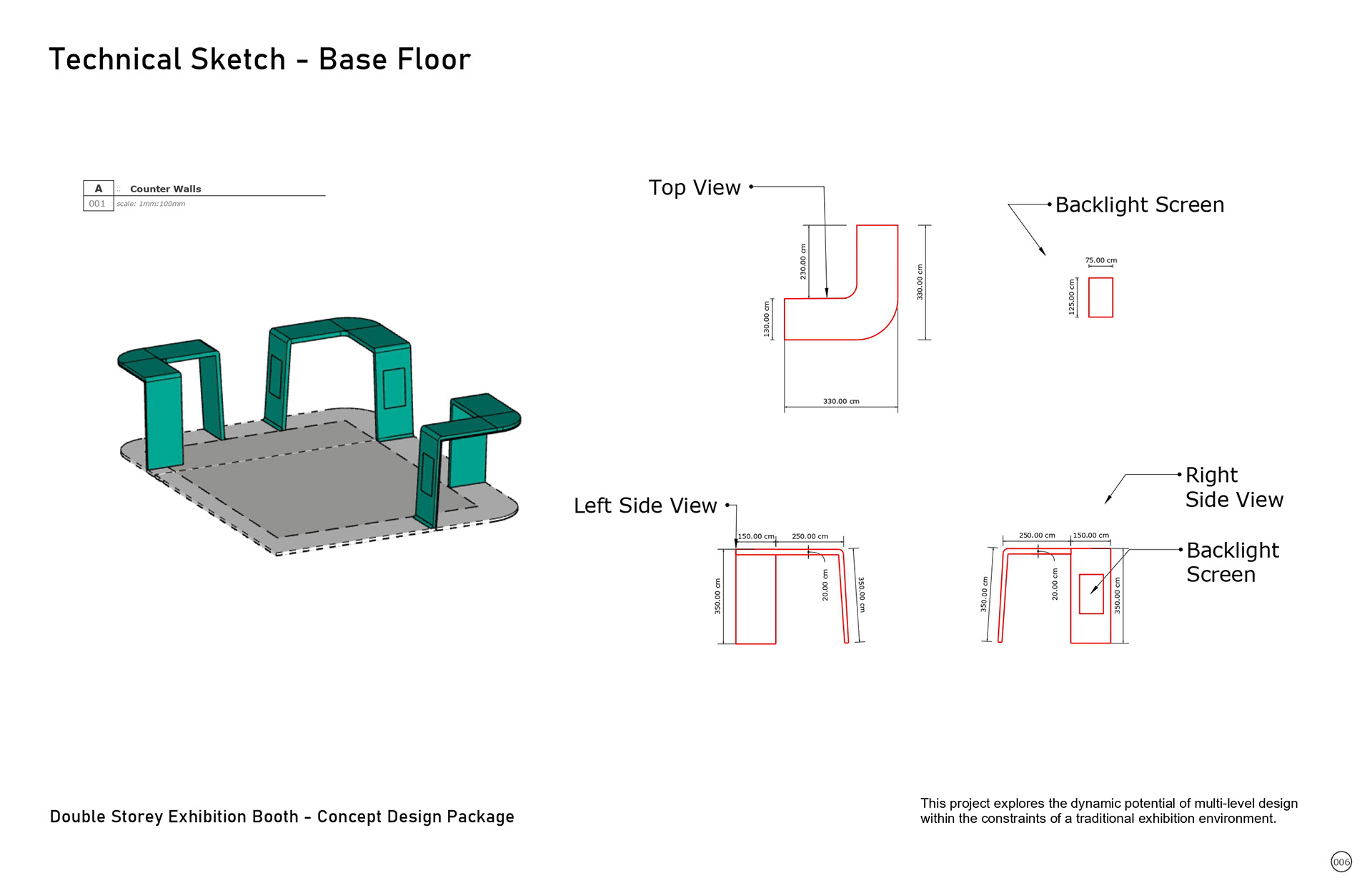

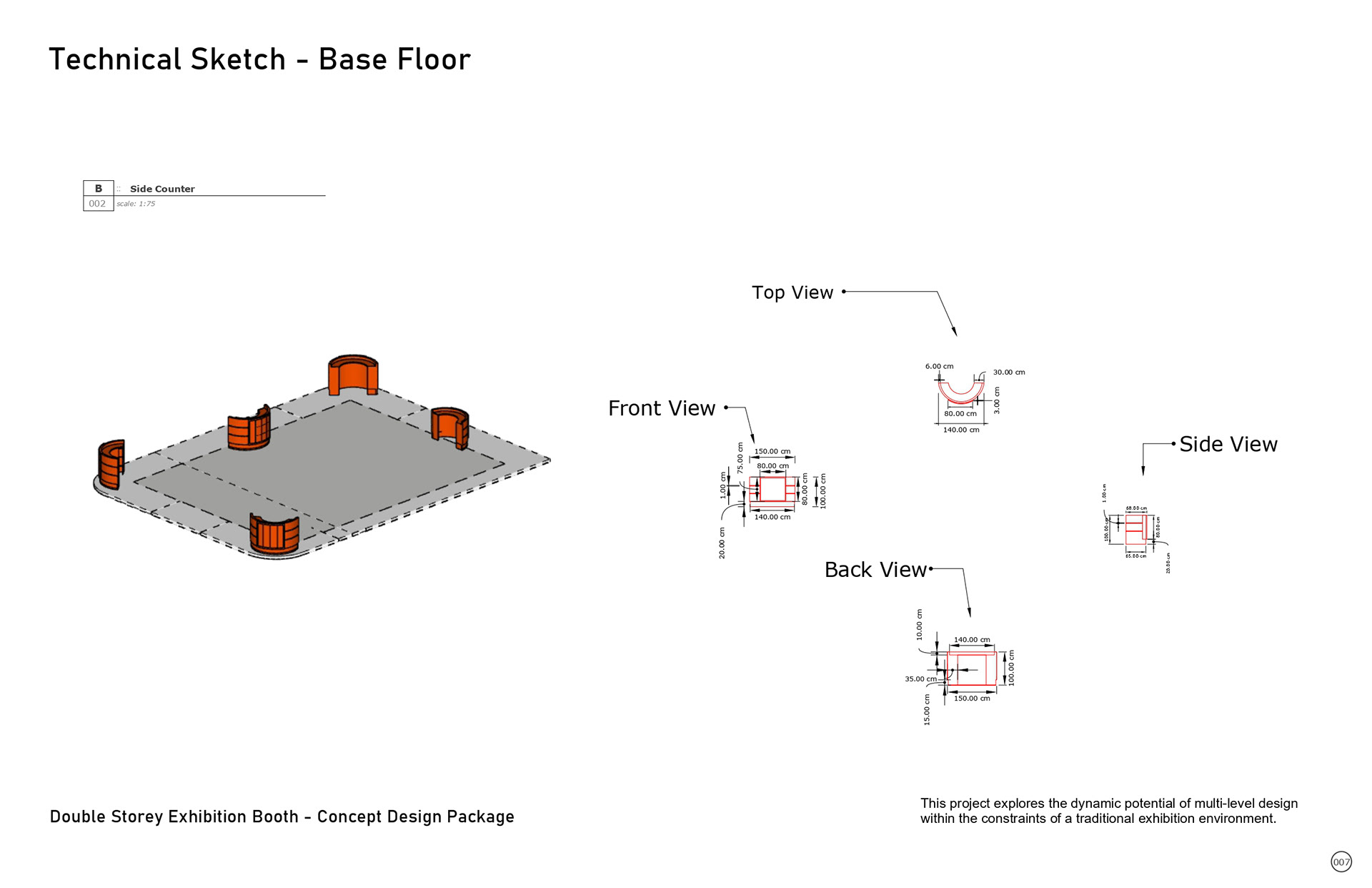

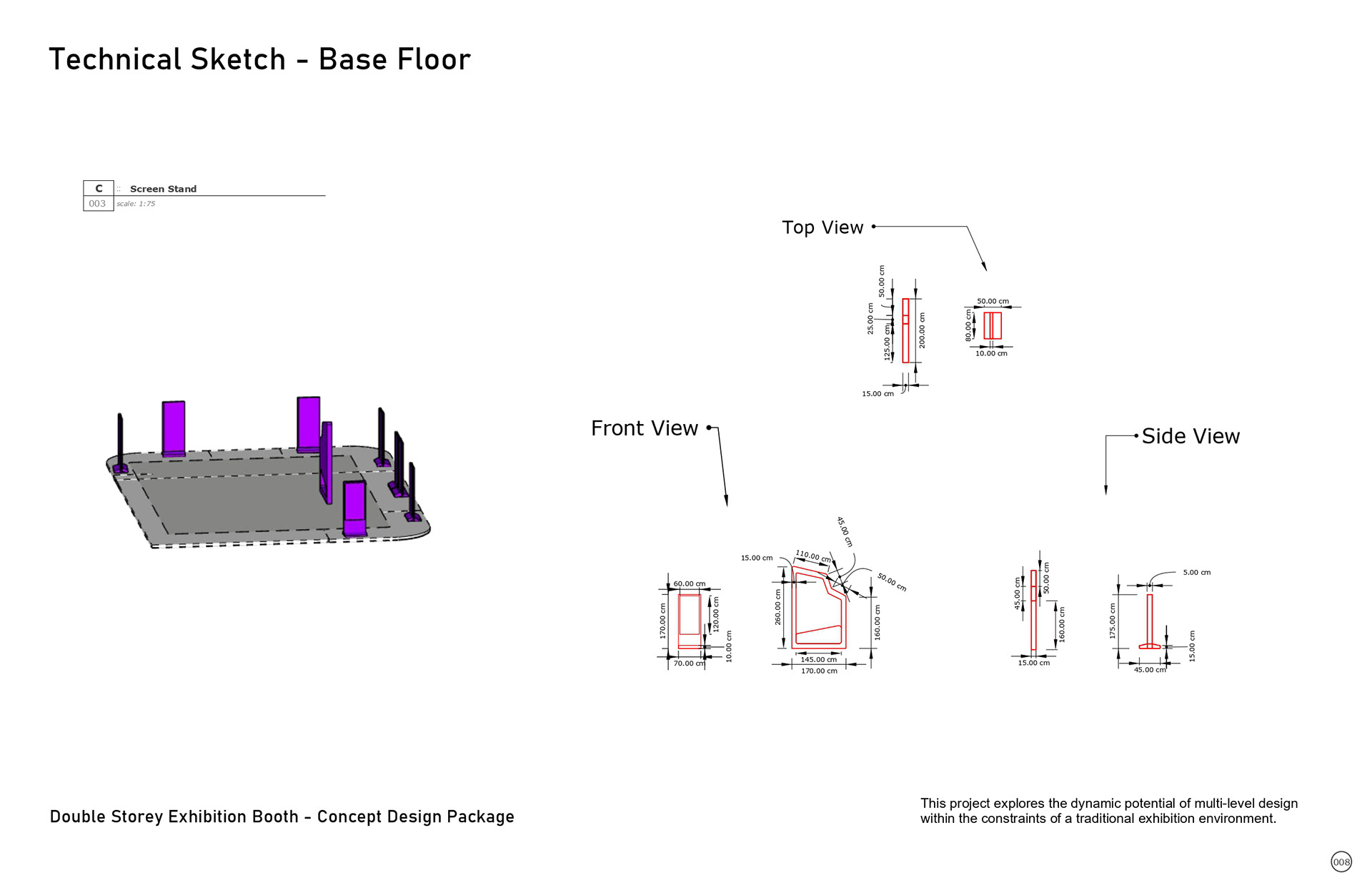

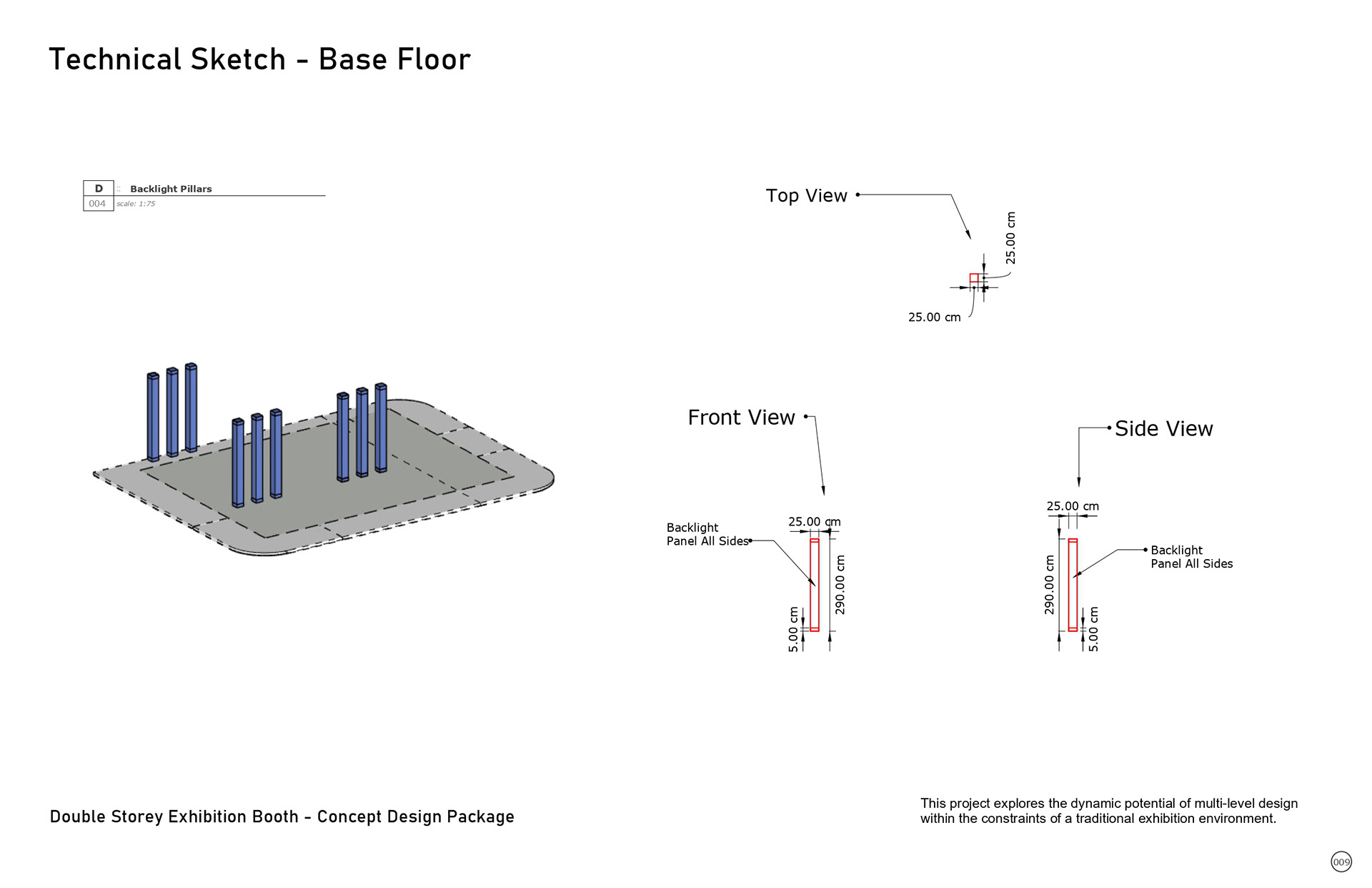

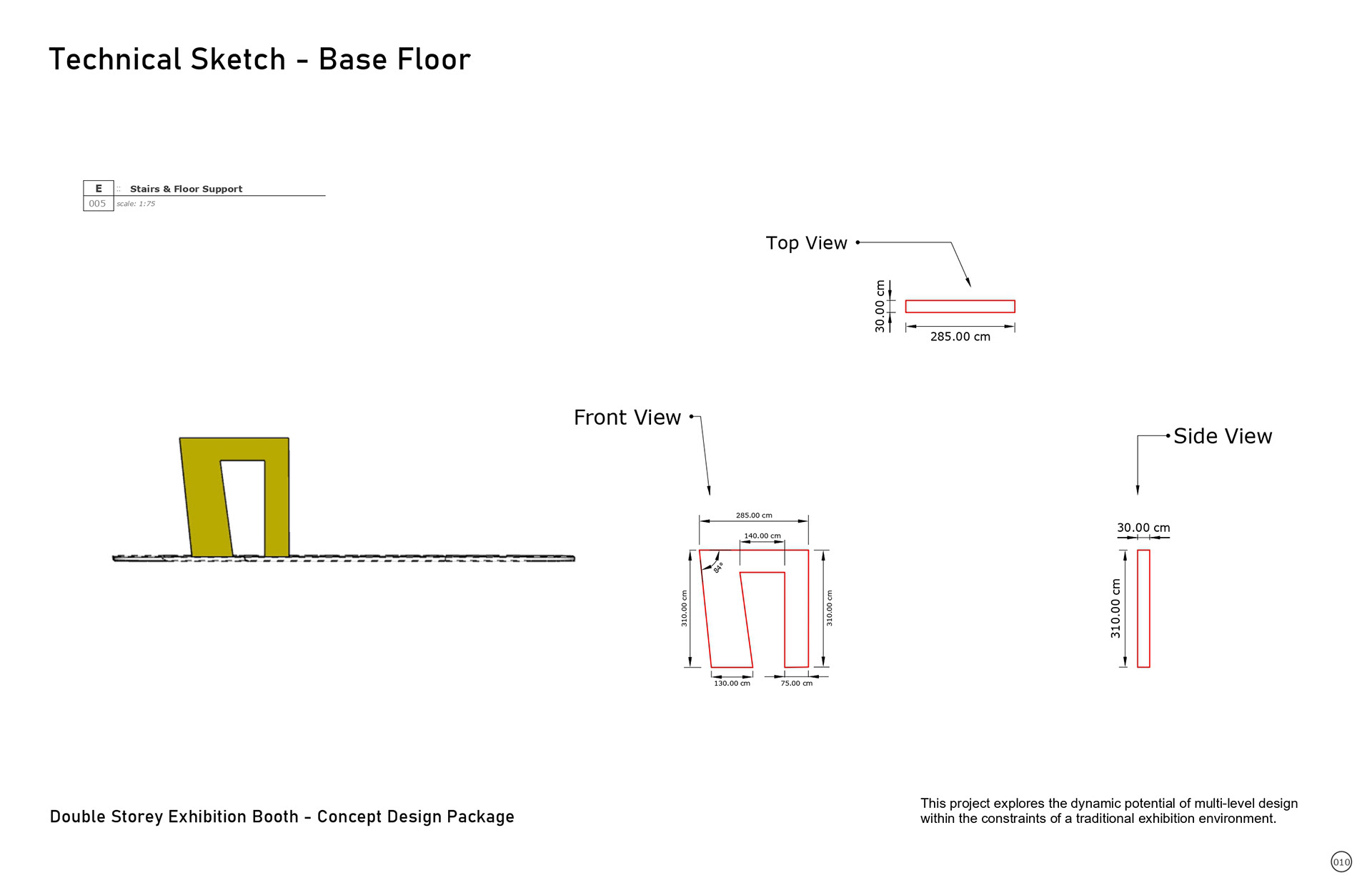

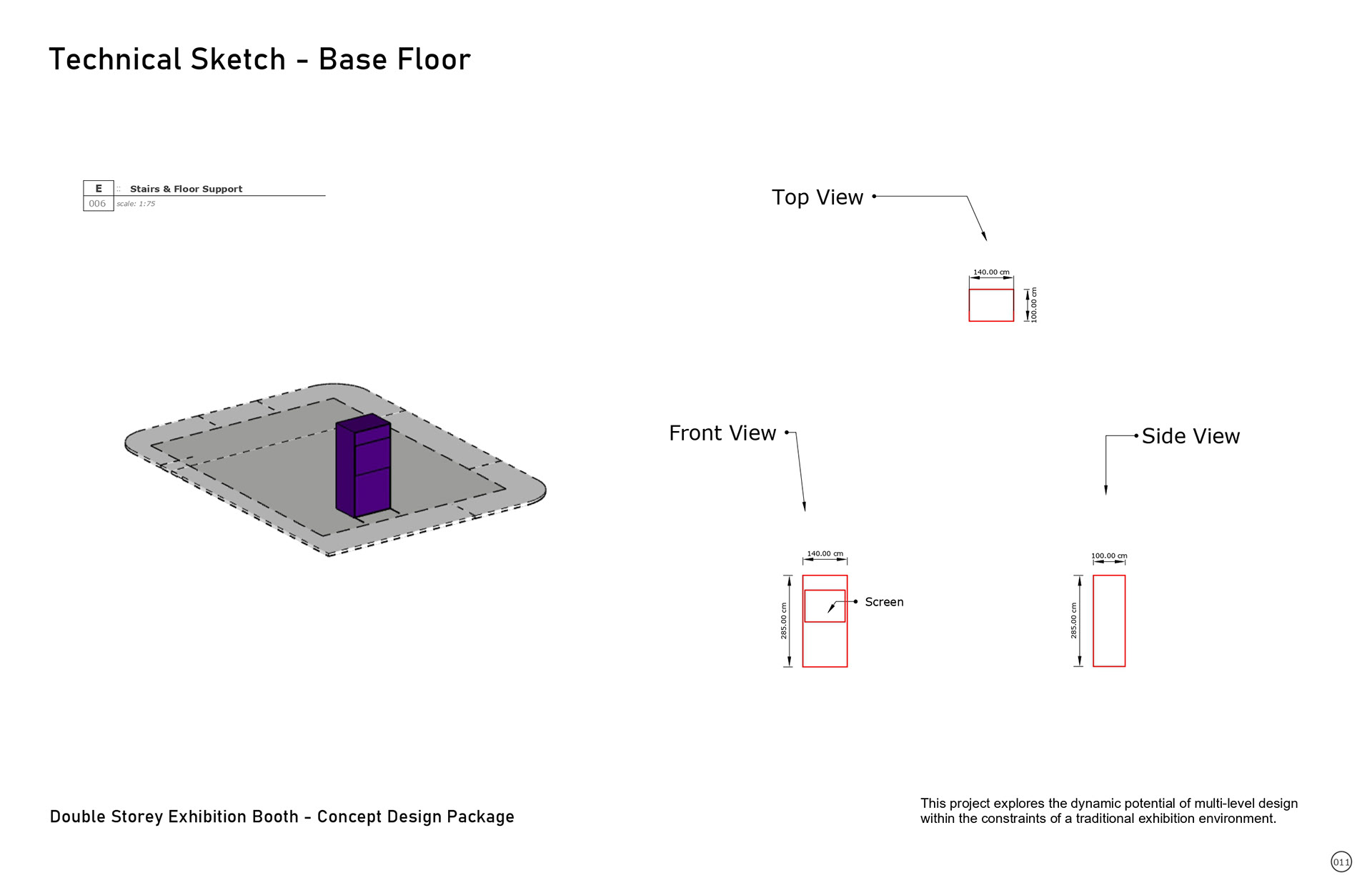

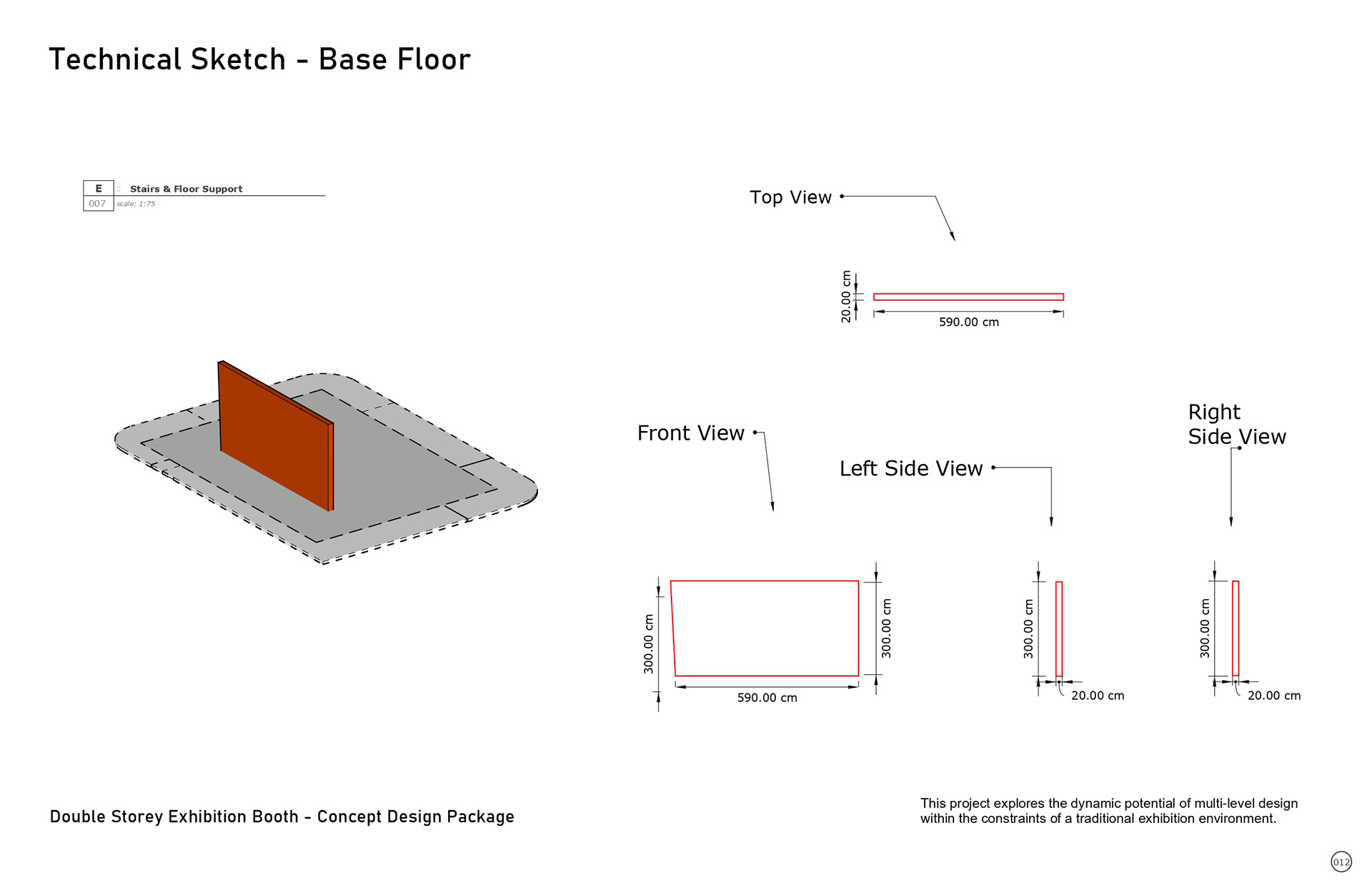

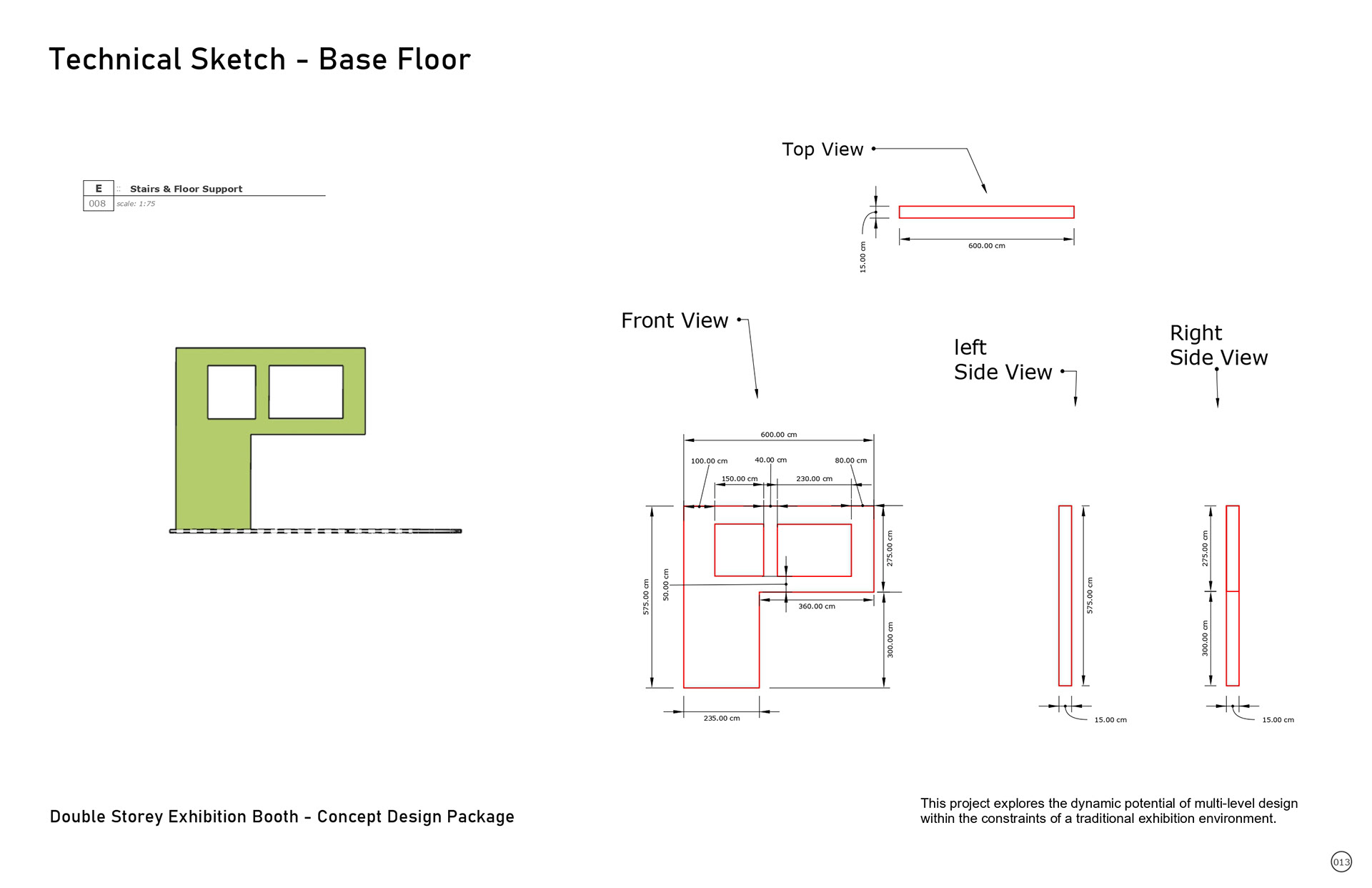

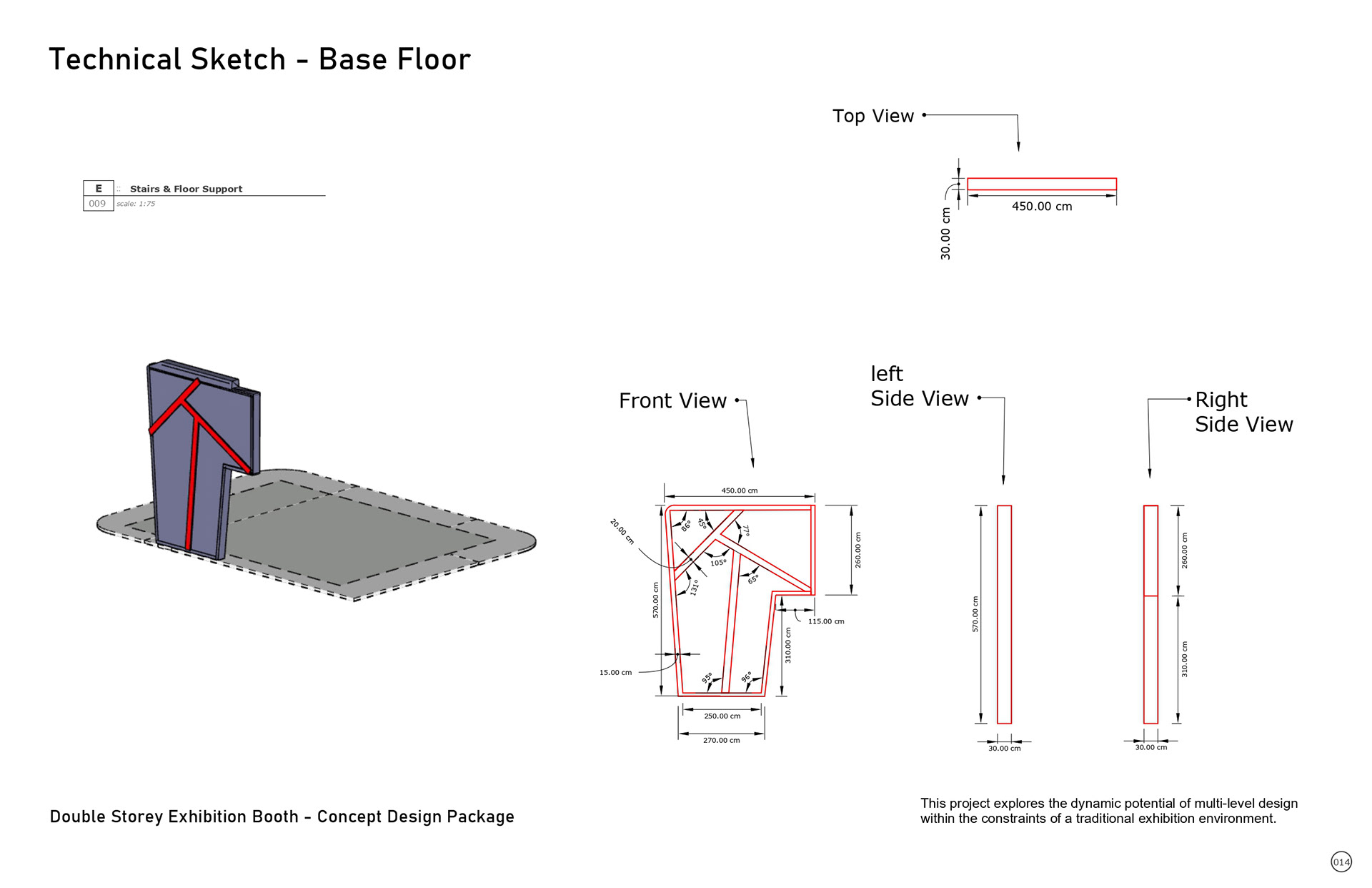

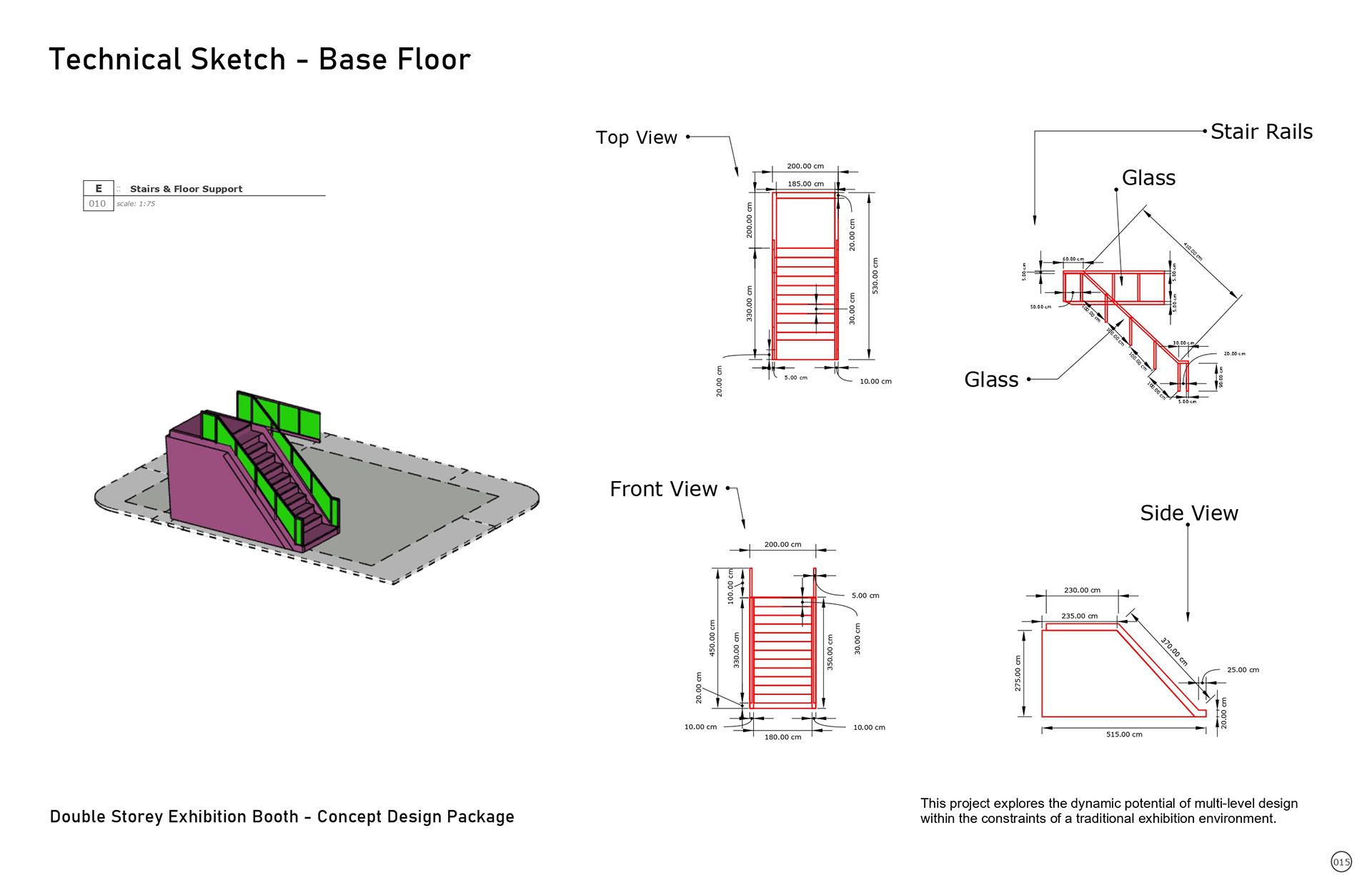

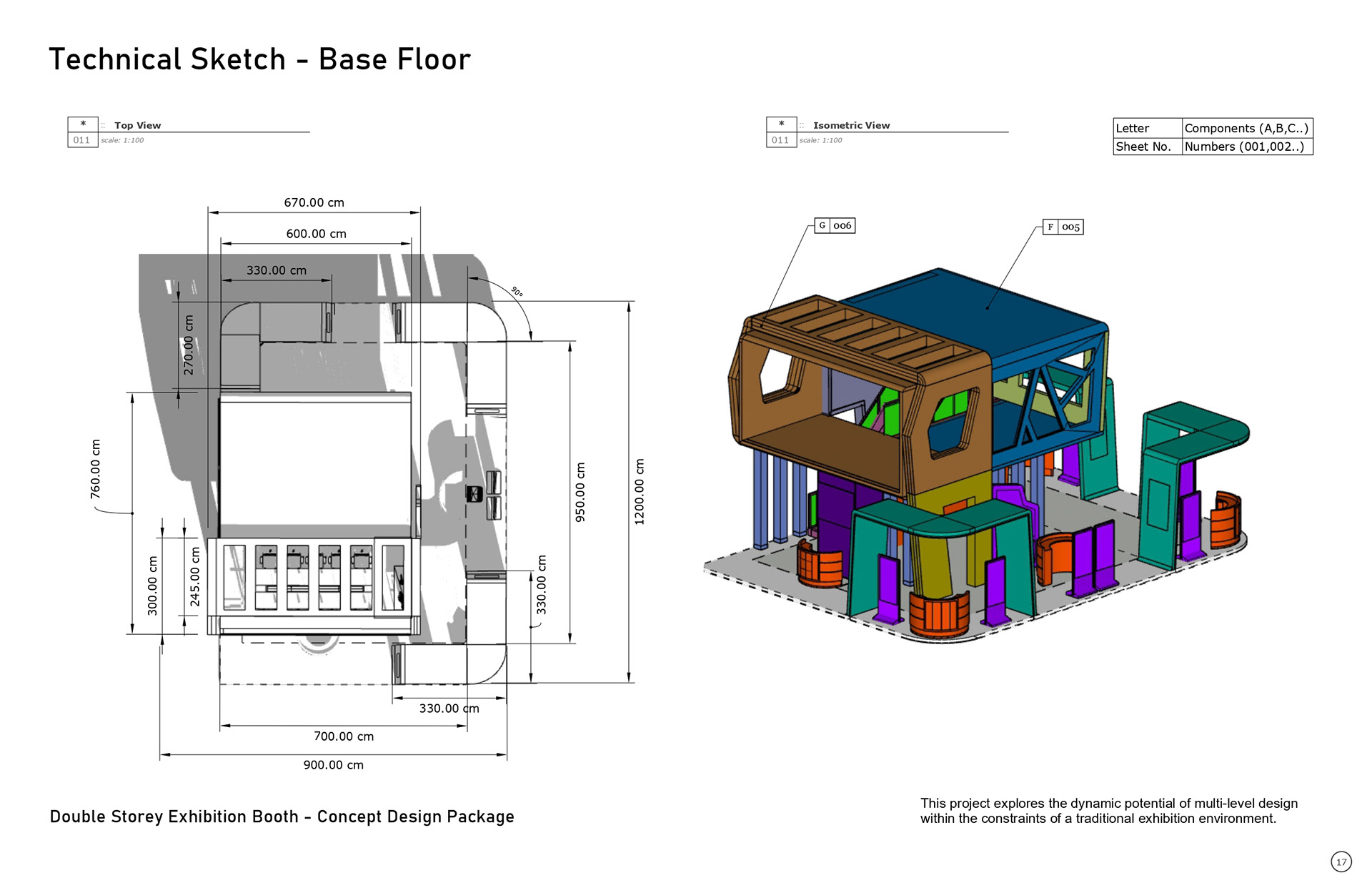

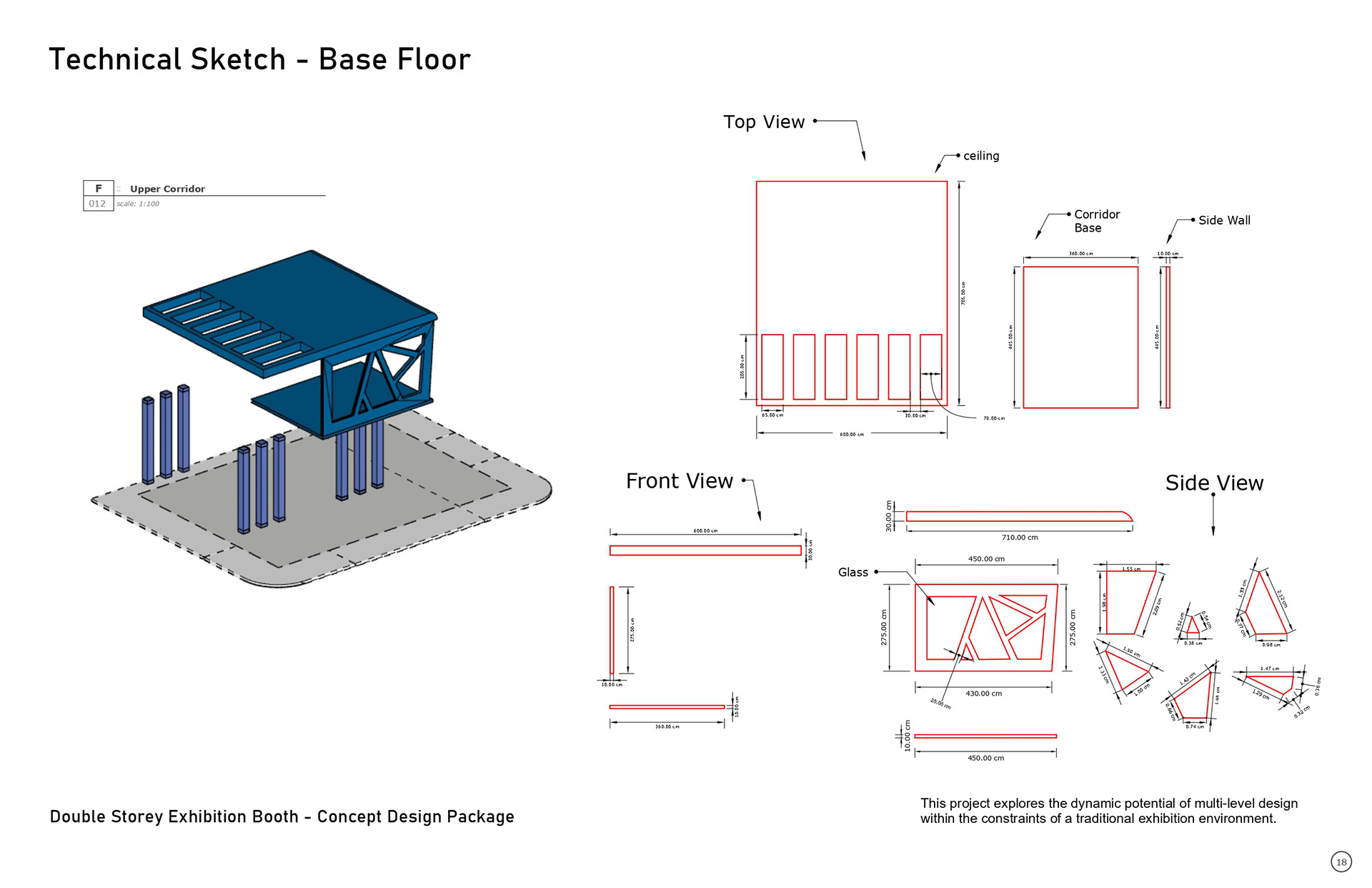

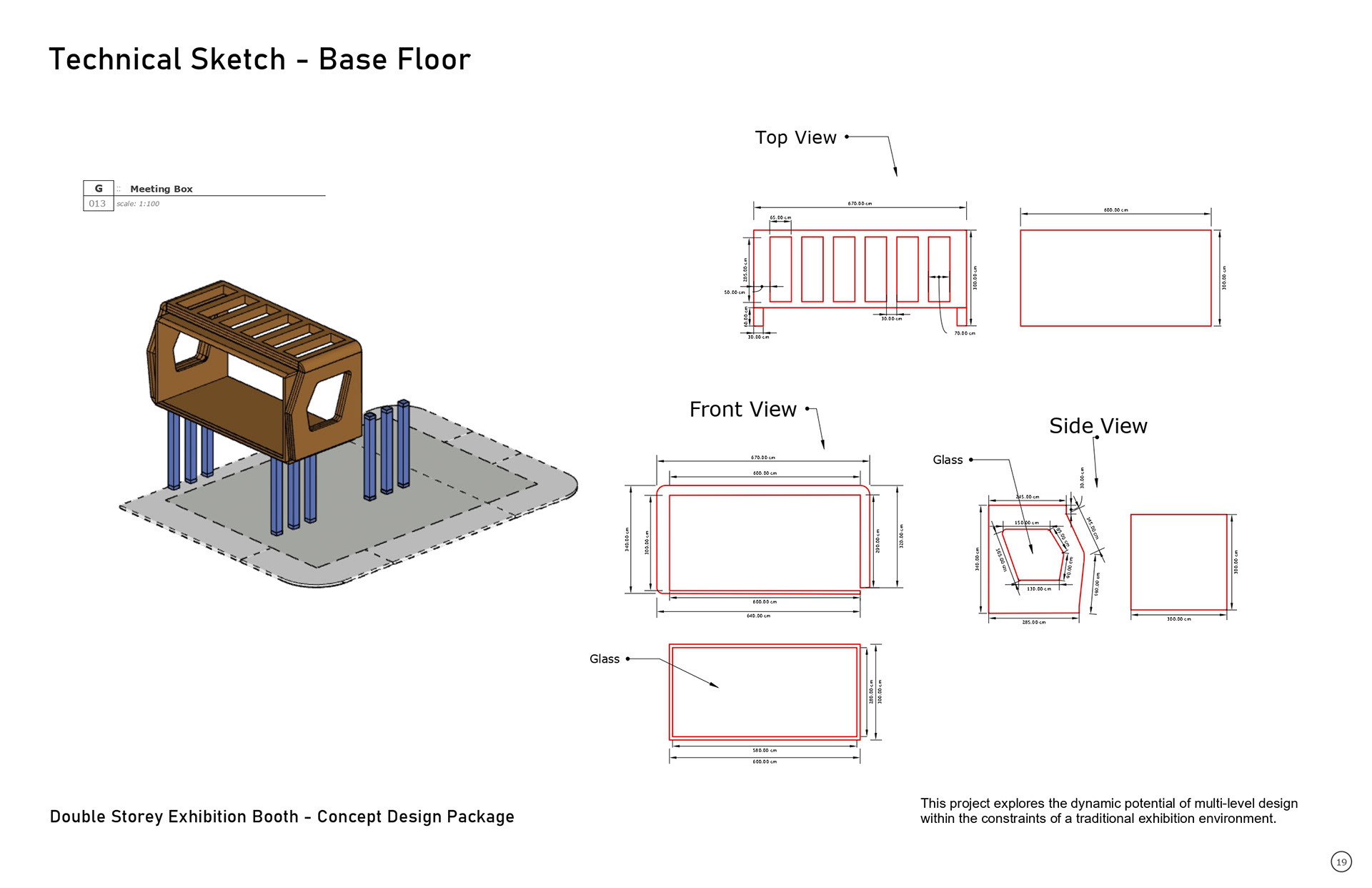

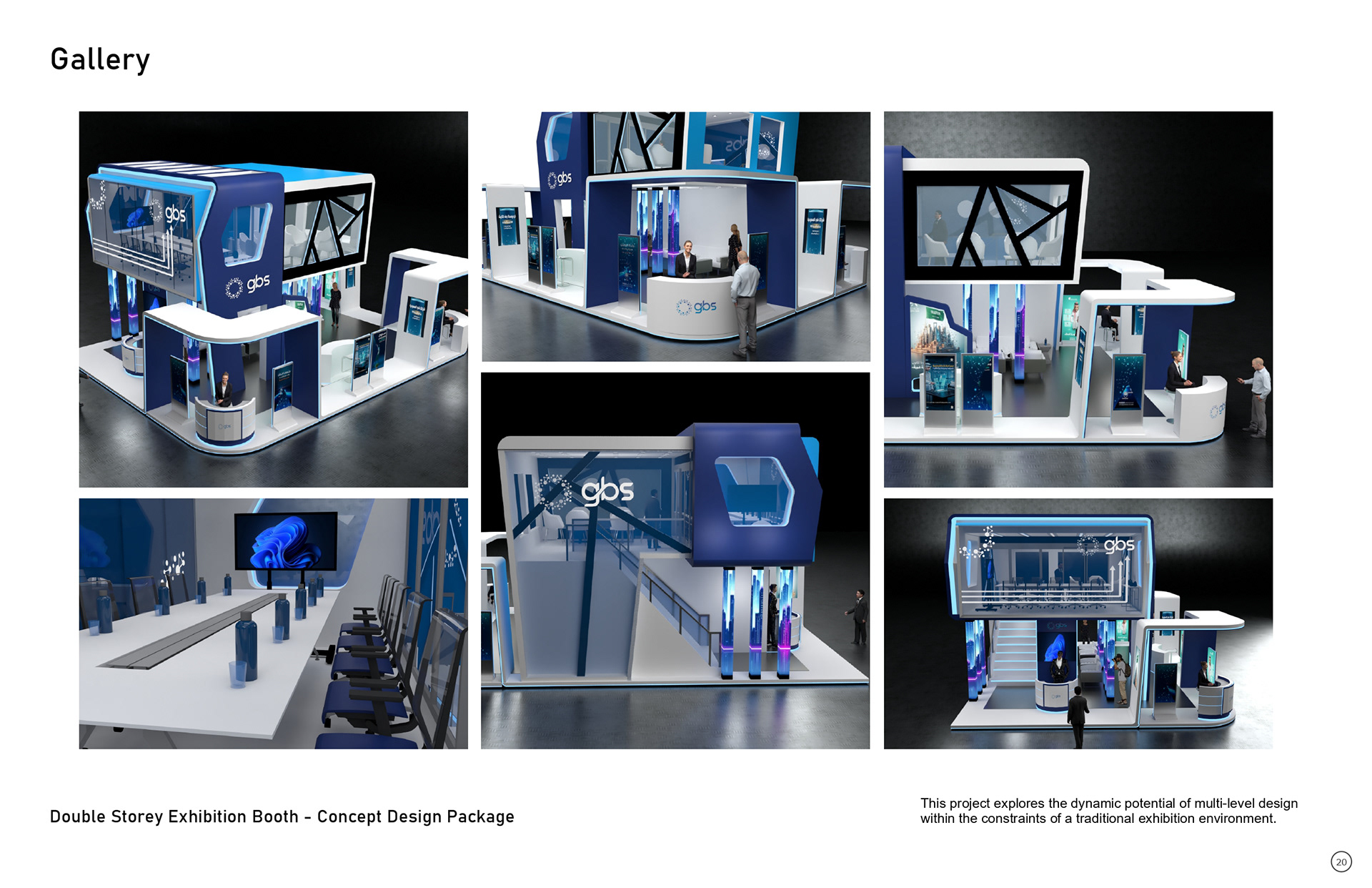

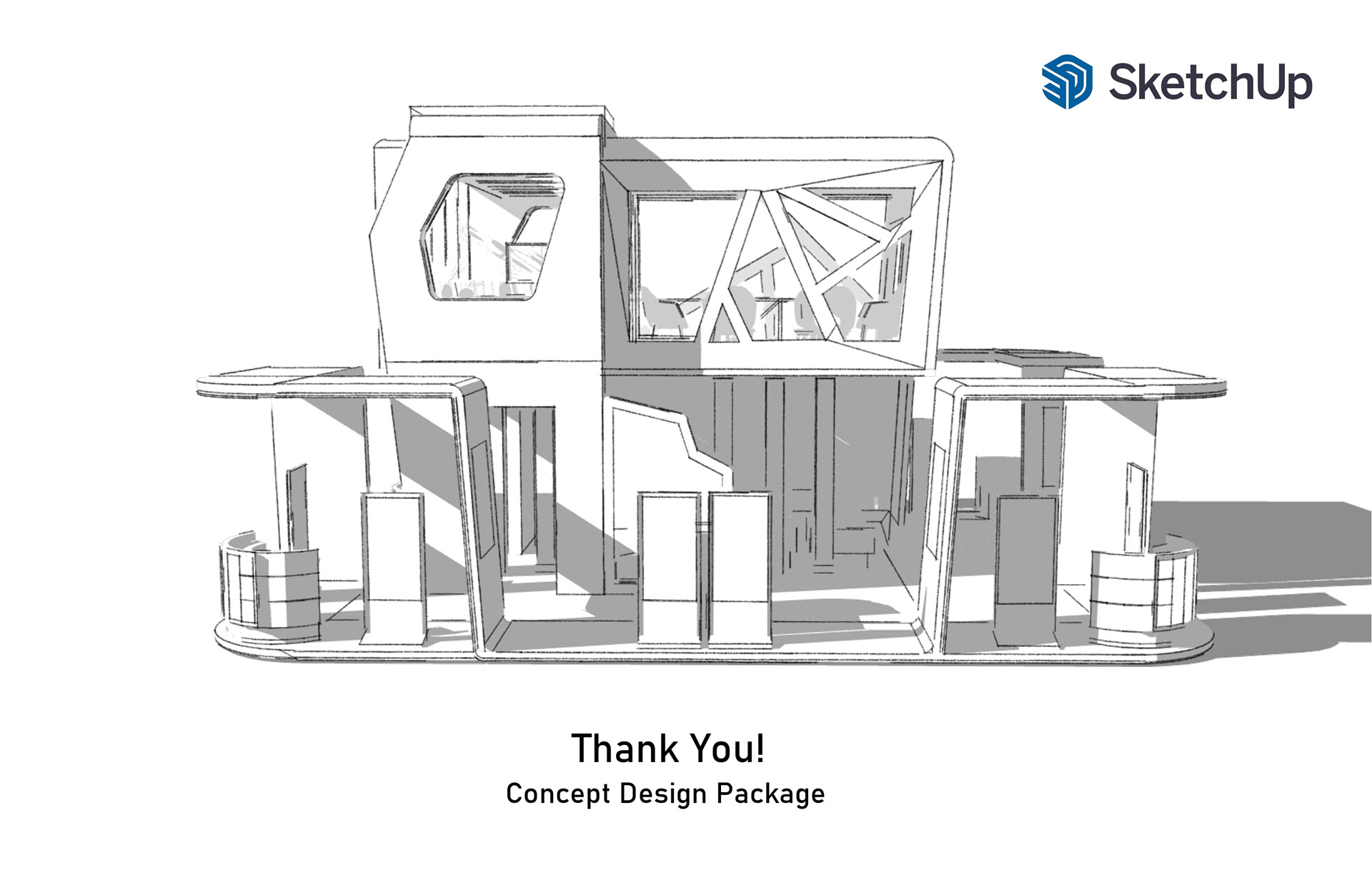

This project involved transforming a fully modeled double-storey exhibition booth into a complete 2D technical manufacturing package. The booth features a premium, multi-level architecture that integrates modern materials, glass panels, backlit elements, and modular structural components. My responsibility was to convert the full 3D concept into accurate, production-ready 2D drawings that manufacturers can use for fabrication, CNC cutting, and on-site assembly.

The design is inspired by contemporary urban architecture, emphasizing clean geometry, transparency, and high-end visitor flow. The upper storey functions as a VIP meeting lounge. At the same time, the lower level includes reception counters, screen stands, backlit pillars, and interactive structures, all of which required precise breakdown and dimensional detailing.

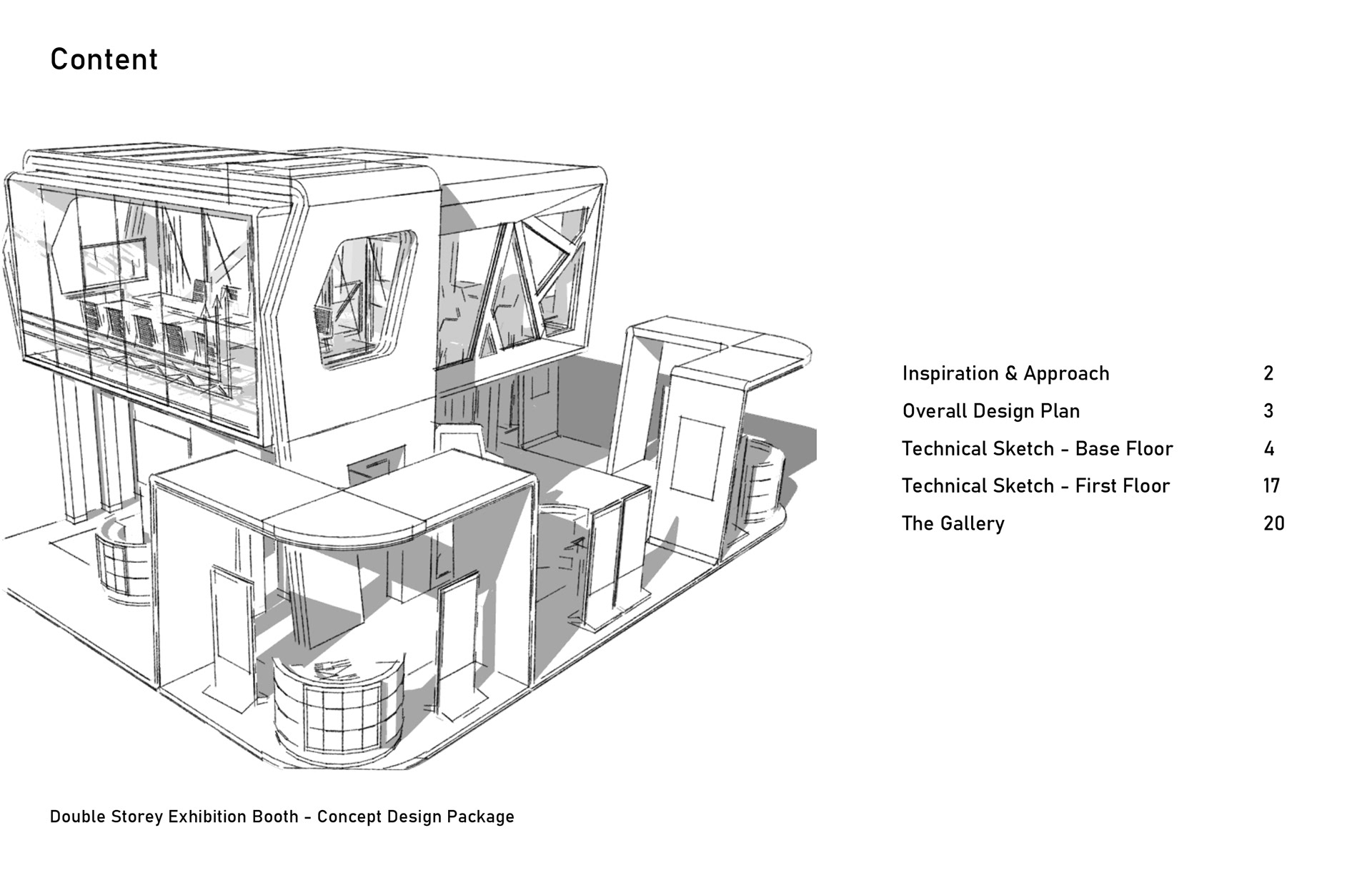

Scaling & Sheet Mapping

- To ensure clarity for on-site teams and fabricators, I implemented:

- Multiple scale systems (1:75, 1:100, 1mm:100mm)

- A consistent sheet nomenclature (A-001, B-002…)

- A layout plan showing how each piece fits within the final build

Tools Used

- SketchUp Pro (Modeling & base reference)

- SketchUp Layout (2D drafting & production drawings)

- V-Ray (For preview renders and visual checks)

- Adobe Illustrator (Element creation)